HSL-CNC3826 Mochini o Iketsetsang oa Khalase

Lisebelisoa

| Che. | Lebitso | Qty | Mohlala |

| 1 | Khaola li-dongle | 1 |

|

| Ntlafatsa dongle (ho latela sistimi) | 1 |

| |

| 2 | Thipa e Sehang | 2 |

|

| 3 | Lebili la ho Seha | 2 | Mabili a mosehla (a nang le lisekere) |

| 4 | Wrench e ka hare ea hexagonal | 1 |

|

| 5 | AC contactor LCIROM5N | 1 |

|

| 6 | belofo ea makenete 4V21008B(24V) | 1 |

|

| 7 | Litlhaloso tsa mokhanni oa Servo | 1 | V6.1 |

| 8 | Letlapa la mouse, keyboard | 1 |

|

| 10 | Phetoho ea ho atamela | 1 |

|

| 11 | Lithae tsa Cable | 50 |

|

| 12 | Oli e entsoeng ka letsoho | 1 |

|

| 13 | Khokahano ea lipeipi tsa moea plug e potlakileng | 1 |

|

| 14 | Leibole pampiri | 5 |

|

Thepa Selelekela

Moetso ona ke mochini oa ho itšeha oa khalase, o kopanyang khalase ea othomathike ea ho ngola le mochini oa ho itšeha o iketsang.E loketse ho itšeha ka khalase e otlolohileng le e bōpehileng ka ho haha, mokhabiso, lisebelisoa tsa lapeng, liipone le mesebetsi ea matsoho.

| Lisebelisoa tsa maoto: | 7 limithara tse lisekoere | ||

| Opereishene: | Khalase e robehileng:2 batho(Batho ba nang le phihlelo ea ho pshatla likhalase ba ka sebelisa hamolemo mokhoa oa ho itšeha) | ||

| Likaroloana | 1. Li-motor tsa boleng bo felletseng le liraka tse tsoang kantle ho naha le likarolo tse ling tsa boemo bo holimo li netefatsa ho nepahala le botsitso ba ho itšeha ka khalase, li na le bophelo bo bolelele ba ts'ebeletso mme li ka kopana le ho seha libopeho tse fapaneng tsa khalase;2.Integrated rail, exclusive patent, cut glass na le ho nepahala ho phahameng;3.Tafole ea mochine e entsoe ka metsi a sa keneleng mollo, mocheso o phahameng le o tlaase, le lisebelisoa tse thibelang ho senya, tse ke keng tsa senyeha; 4.Tsebetso ea ntlha ea ho skena ka infrared le ts'ebetso ea thempleite ea sebopeho se ikhethileng sa infrared; 5.Highly bohlale ho itšeha optimization software, e leng haholo ntlafatsa tšebeliso khalase le ho fokotsa litšenyehelo tlhahiso; 6.Ts'ebetso ea ho phaphamala ka moea, ho ntlafatsa katleho ea mosebetsi, ho tla le mochine o jarollang ka ho iketsa le mochine oa karohano; 7.Injene ea oli ea othomathike le ts'ebetso ea phetoho ea khatello ea othomathike ea mochini oa ho itšeha, ho netefatsa ka katleho botsitso ba ho itšeha le phello ea ho itšeha; 8.Ha ho na litlhoko tse khethehileng bakeng sa basebetsi, ts'ebetso e bonolo le tsamaiso e bonolo. | ||

| Sehlopha | Morero | Tataiso ea Morero | |

| Mesebetsi | Mesebetsi e tloaelehileng | Software ea ho ntlafatsa | 1.Professional glass cutting and optimized typesetting function: ntlafatsa haholo sekhahla sa ho itšeha likhalase le katleho ea tlhahiso.2.E tsamaellana le software e ntlafalitsoeng ea OPTIMA ea Setaliana le khoutu e tloaelehileng ea G ea software ea GUIYOU: Lemoha bokahohle ba lifaele tsa mefuta e fapaneng.3.Tlhahlobo ea phoso le ts'ebetso ea alamo: E ka rekota ka bo eona boemo bo sebetsang ba mochini ts'ebetsong ea tlhahiso, alamo ea phoso le mathata a bonts'a. |

| Fiber laser positioning | 1. Ho fumana le ho beha likhalase ka mokhoa o ikemetseng: Tekanyo e nepahetseng ea boemo ba 'nete le angle ea ho kheloha ea khalase, ho hlokomela phetoho ea othomathike ea tsela ea ho itšeha ea lehare, le ho ntlafatsa ts'ebetso.2. Ho hlahlojoa ka mokhoa o bohlale: Mobutla o ka hlahloba lintho tse bōpehileng ka bohlale 'me oa iketsetsa litšoantšo ho lemoha ho seha li-contour. | ||

| Theknoloji ea ho fokotsa | Khatello ea lehare la ho itšeha e laoloa ke valve ea electromechanical precision e laolang khatello, 'me silinda e sutumelletsa khatello ka mokhoa o ts'oanang ho etsa hore lehare le lekane hantle holim'a khalase ho khaola, ho qoba ho tlōla ka lebaka la mathata a boleng ba khalase. | ||

| Khalase ea ho senya mosebetsi | Kenya molamu oa ejector sethaleng sa ho itšeha.Silinda e sututsa molamu oa ejector ho khaola khalase. | ||

| Ho Tsamaea ka Mochini | Foreimi e ka tlase ea mochini e na le mabili a 4 a nylon ea bokahohleng ho thusa moreki ho sututsa motsamao.Ka mor'a ho beha, maoto a 4 a lokisoa ho tšehetsa ho ts'oaroa ho tsitsitseng ha mochine | ||

| Mosebetsi oa boikhethelo | Ho ngola ka ho iketsa | Kenya sebaka sa ho ngola ka letsoho.Ho ea ka litlhoko tsa bareki, mochine oa khatiso o hatisa lileibole tse rekotang tlhahisoleseding ea khalase.Leibole le sebelisoa holim'a khalase e tsamaellanang le moqomo oa ho ngola.(Re khothaletsa bareki ho hlophisa mosebetsi oa ho ngola) | |

| LipalangoangLikaroloana | Sethala sa ho itšeha se na le lebanta la conveyor.Ha ho hlokahale ho tsamaisa khalase ka letsoho.Khalase e sehiloeng e ka fetisetsoa tafoleng ea moea e phaphametseng e phunyeletsang ka lebanta la conveyor, 'me ts'ebetso ea ho senya e etsoa holim'a tafole e pshatlang khalase.(Ho hlokahala ho reka moea floating khalase pshatla tafole) | ||

| Sehlopha | Morero | Tataiso ea Morero | Hlokomela | |

| Sebopeho sa sehlahisoa | Karolo ea mochini | Mochini foreimi | Phekolo ea botsofali ka mor'a ho cheselletsa likarolo tse teteaneng.Letlapa la ho lokisa mabala a mahlakoreng le sebetsoa ka ho sila ka gantry ho netefatsa ho nepahala le botsitso. |

|

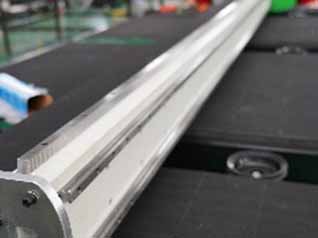

| Sehlahisoa se sehang | Terene e nang le patente ea aluminium e entsoeng ka patente ea T-WIN, ho nepahala ho phahameng, lerata le tlase, sebopeho se ratoang sa lisebelisoa tse phahameng. | |||

| Beam e lehlakoreng | Seporo sa aluminium se nang le tokelo ea molao se kopaneng se otlolohileng se chitja, matla a mabili a terene, a bilikang tseleng, likhohlano tse tlase li ka netefatsa ts'ebetso e tsitsitseng ea borokho bo sehang. | |||

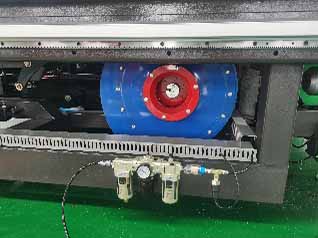

| Fane | Feni e etselitsoeng matla a phahameng, khatello e matla ea moea le phallo e kholo, e netefatsa ho phaphamala ha khalase e boreleli. | |||

| Karolo ea tafole | Boto e sa keneleng metsi e phahameng haholo ke substrate, 'me bokaholimo bo koahetsoe ke maikutlo a liindasteri a anti-static.Netefatsa tšebeliso e tsitsitseng libakeng tse mongobo. | |||

| Ho khaola hlooho | Jeremane Bohle | |||

| Gear Rack | Ho amohela sebopeho sa helical rack le pinion ho ntlafatsa matla a holim'a leino le ho fokotsa lerata ka nepo | |||

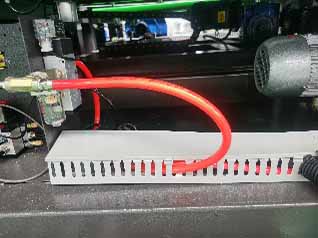

| Hula ketane | Matla a phahameng 7525 ketane ea ho hula e khutsitseng | |||

| Phepelo ea oli | Phepelo ea oli ea lehare la ho itšeha e nka mokhoa oa ho tlatsa oli o ikemetseng oa pneumatic, ntle le ho kenella ka letsoho. | |||

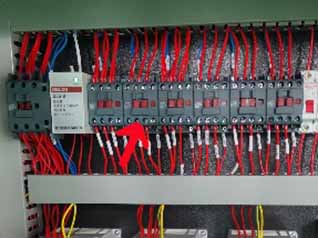

| Likarolo tsa motlakase | Ho khaola mochine oa koloi | 2 e beha taolo e phahameng ea indasteri e inehetseng ea servo motor bakeng sa taolo e nepahetseng le ts'ebetso e bonolo. |

| |

| Molaoli | Karete ea boto ea taolo e khethehileng ea Huashil, sistimi ea taolo ea Gugao PLC. | |||

| Optical fiber | E sebelisa lisebelisoa tsa laser tsa Panasonic tse tsoang kantle ho naha ho tsoa Japane. | |||

| Pontšo | Pontšo ea Dell, Tlhaloso e phahameng le ts'ebetso e tsitsitseng | |||

| Khomphutha e amohelang | Moamoheli oa likhomphutha tse sebetsang hantle bakeng sa taolo ea indasteri;pontsho ya boemo bo hodimo ba lebitso. | |||

| Element | Likarolo tse tsoang kantle ho naha tsa machaba tsa taolo ea mofuta oa pele joalo ka OMRON, AirTAC. | |||

| Tekheniki Parameters

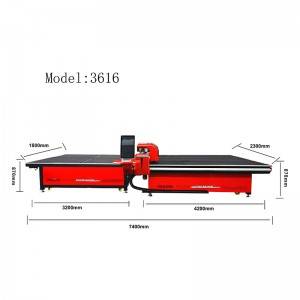

| Litekanyetso tsa mochini | Litekanyo | Bolelele * bophara * bophahamo: 3350mm * 3000mm * 1400mm |

|

| Boima ba 'mele | 1200kg |

| ||

| Bophahamo ba tafole | 880±30mm(Maoto a fetohang) | |||

| Litlhoko tsa matla | 380V, 50Hz | |||

| Matla a kentsoeng | 7.5kW (Sebelisa matla3KW) | |||

| Moea o petelitsoeng | 0.6Mpa | |||

| Lisebelisoa tsa ho sebetsa | Khaola boholo ba khalase | MAX.2440 * 2000mm |

| |

| Khaola botenya ba khalase | 3-19 limilimithara | |||

| Lebelo la beam ea hlooho | X axis 0 ~ 200m / min (e ka hlophisoa) | |||

| Lebelo la hlooho | Y axis 0 ~ 200m / min (e ka hlophisoa) | |||

| Ho potlakisa ho potlaka | ≥8m/s² | |||

| Setulo sa thipa se sehang | Ho itšeha hlooho ho ka potoloha likhato tse 360 (ho itšeha hantle ka mela e otlolohileng le libopeho tse ikhethang) | |||

| Ho seha ho nepahala | ≤± 0.2mm/m (Ho ipapisitsoe le boholo ba mohala oa ho itšeha pele khalase e robeha) | |||

Lethathamo la Tlhophiso